Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

On the basis of our own assembly and assembly production, we carry out the following types of assembly:

We offer our customers both urgent installation of pilot batches of products within a few days, and serial production of small, medium and large batches of products according to an agreed schedule, and we guarantee strict adherence to the agreed terms of installation.

Our assembly and assembly production is equipped with modern and professional equipment for performing any type of assembly.

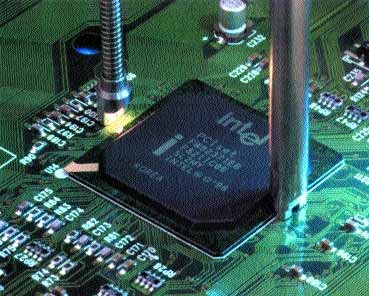

The leading place in the overall production process is occupied by two high-speed automatic assembly lines based on the SMD component installers of the South Korean company Mirae Corporation: MiraeMx-400, MiraeMx-200P, MiraeMx-400L, MiraeMx-400LP. Both lines are equipped with conveyor convection thirteen-zone reflow ovens A70-j132 and precision automatic paste printers HP-520 and HP-620. One of the lines is capable of assembling dimensional printed circuit boards, with a maximum board size of 750mm x 460mm.

This configuration of the equipment allows us to achieve high performance in the installation of planar components, observing all standards for the quality of soldering. The throughput of each line is up to 70,000 components per hour.

| Our site for manual assembly and assembly of finished products is represented by wide production capabilities. Workplaces on the site are equipped with all the necessary soldering equipment and professional assembly and assembly tools. For the performance of high-quality installation work, we engage in our production only qualified radio installers of 5-6 categories. Our fitters are able to maintain the overall high pace of the production process, jointly completing up to 400,000 manual rationing points per month. |

Well-established technology and the experience of our specialists allow us to carry out lead-free, lead-free and mixed assembly of electronic products of any complexity and in various volumes.

For the assembly of printed circuit boards, we use only imported, well-proven consumables - solder pastes, solders, fluxes and washes.

In the production of electronic products in our enterprise, we can provide customers with various additional assembly and technological services:

All of our manufacturing facilities are built to international ESD standards for electronic products and PCB contract assembly.

Constantly improving the technical capabilities of our assembly production, we give top priority to the quality of our products. The entire technical process of installation production is initially formed in such a way that each product, upon completion of a certain installation operation, undergoes an intermediate check in the Technical Control Department of our enterprise. For these purposes, the Quality Control Department uses various modern control and measuring equipment.

| In case of mass execution of planar installation works, the quality control of the installation is carried out at the automatic optical inspection station MIRTEC MV-7xi, with a check speed of 1,722 mm² of the area of the mounted board per second (0.28 s / frame).In the event of a defect detected, in the process of checking the product for compliance with the wiring diagram and the quality of soldering, the technological complaint files in electronic form, generated by the station for each rejected board, are sent to specialized workplaces of installers-repairmen, for manual elimination of all defects in machine installation. | |

| In the process of assembling boards with components of hidden soldering (BGA), our production has introduced a system of selective control of BGA-components for large-scale assembly, and full 100% quality control of soldering, with small batches of boards with BGA-components. For this, the staff of the Quality Control Department use the stations of the desktop optical inspection system ERSASCOPE . | |

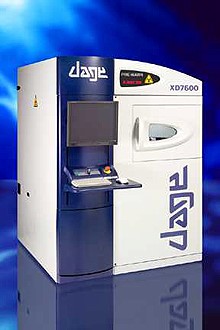

| Particularly difficult components for visual inspection are tested on the XD7600 X-ray inspection unit, with the possibility of providing the customer with an electronic report on the quality of the installation of BGA components. ` | |

| Elimination of various assembly defects found on similar products (for example: replacement of components in BGA, LGA, QFN cases, etc.) is carried out using the DEN-ON RD-500III repair center. |

Our technologists apply an individual approach to any incoming order, develop the optimal stages of production, taking into account all the technical nuances and features of the future product. For each individual order, its own technological map of the passage through the production is issued. All technical processes are drawn up in compliance with the basic rule: "Continuous quality control, from the receipt of an order at the warehouse to the issuance of the finished product to the customer. "

With all this, we provide a guarantee of impeccable quality when fulfilling your orders! To place an order, send the assembly drawing and specification indicating the quantity and the required delivery time via the feedback form.

Order form

Do you have any questions, or would you like to speak directly with a representative?